Microprocessor Active Use In Food Reduction

To Keep Track Of Our Food and Reduce Food Spoilage

Author’s Note

This paper was prepared for ENGL 210, Professor Delamare’s class on Writing for Engineering.

Table of Contents

Introduction————————————————————————- p. 3

Objectives————————————————————————— p. 4

Preliminary Literature Review————————————————— p. 5

Technical Description————————————————————- p. 9

Budget——————————————————————————- p. 12

References————————————————————————— p. 14

Appendix A – Task Schedule—————————————————– p. 16

List of Illustrations

Figure 1 Smart Fridge Camera—————————————————— p. 5

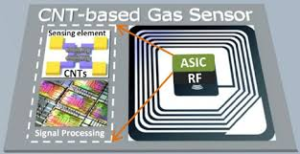

Figure 2 Carbon Nanotube Sensing Gas——————————————- p. 7

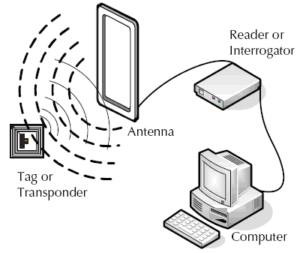

Figure 3 Carbon Nanotube RFID————————————————— p. 7

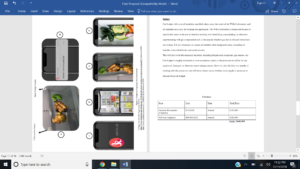

Figure 4 RFID System————————————————————— p. 8

Figure 5 C2Sense Gas Sensor Node———————————————— p. 9

Figure 6 Diagram of Spoilage Detection System——————————— p. 11

Figure 7 Graph of Scheduling——————————————————- p. 16

Summary

In residential homes one of the greatest causes of food waste is food spoilage. Spoiled food can also contaminate or spoil other food due to bacteria of the release of ethylene gas. Lastly cleaning up spoiled food in the refrigerator can be a hassle to clean, since spoiled food usually leaves an unpleasant smell. Currently other that expiration dates or using your senses of smell or sight, there is very little tools for food spoilage detection. Senses only detect food spoilage when the food has already gone bad and senses cannot detect food spoilage if the food is not visible in the fridge or forgotten in some crevice. In this paper we explore the possibility of creating an app and system using a combination of up and coming gas sensing technology, made of electro resistor nanotube chips, refrigeration cameras, and monitors already used in smart refrigerators. The gas sensors would be placed in the refrigerator in strategic locations with cameras in different drawers. The app would be stored in the monitors. When the gas sensors sense that food is beginning to rot, it will send the data to the monitor and app. The app will send notifications to your phone and monitor warning you that something is going bad and that you should eat it soon. The app will then show you where the at risk food is located in the refrigerator, and can even show the location on camera. We explore the feasibility and implementation of this technology for residential smart refrigerators with an annual budget of $454,790.

Author’s Note

This paper was prepared for ENGL 210, Professor Delamare’s class on Writing for Engineering.

Introduction

Food spoilage is an issue that is still currently affecting the modern world. Estimates of food loss and waste, state that roughly 1.3 billion tonnes of food produced for human consumption is lost annually (Key Facts, n.d.). While many solutions for food waste has been implemented on food production, a big segment of waste is caused on the consumer level. In particular, around 31 percent of the waste amounting to 133 billion pounds of food, worth 161 billion US dollars, was caused by the retail and consumer level (Key Facts, n.d.). Oftenly neglected is the waste cause by households on the individual level. Unbeknownst to most, the majority of food waste, two thirds precisely, in households is caused by spoilage (Quested et al., 2011). Other than waste, food spoilage affects families economically and consumes time due to cleanup and shopping. An effective means of detecting spoilage, can give consumers the power to prevent food waste caused by expired food, decreasing food waste overall, and increase utility by reducing time consumption and cost.

Presently the only means of spoilage detection and management in most households is the use of scent, sight, and expiration dates on food. However a large portion of produce does not have expiration dates, and your senses of sight and scent only allow you estimate the time till spoilage, or detect food that has already expired. Lastly hidden or forgotten items in refrigerators cannot be detected by any of these means. With the advent of smart refrigerators containing monitors and apps, data can be collected, organized, and then displayed to the user allowing for more user control. In this paper we propose a 2 step solution for food spoilage prevention, where the first step includes placing C2sense gas sensing carbon nanotube chips, or C2sense gas sensing sensors, and cold proof Smart Fridge Cameras in smart refrigerators. These components will be purchased from C2Sense, a leading company in the new gas sensing technology field, and placed in strategic locations in the fridge to sense spoilage, collect and organize data, and transfer this data to an app on the Smart Fridges monitor. The Second Step is to create an App which we called Kitchen Aid that uses the data from the C2Sense sensors to send notifications to your phone or smart kitchen monitor, alerting that a certain food is starting to spoil, and that you should consume it. The app would inform the user where the expiring food is located in the fridge and allow the user to use the Smart fridge cameras to look at the compartment where the expiring food is located from either your phone or smart fridge. These two parts in conjunction would detect and prevent food spoilage.

Objectives

Our main object is to test the feasibility of applying the C2Sense gas sensing technology in residential refrigerators and creating an app that can use this data to detect food endangered of expiration. The app will also estimate the amount of time left before expiration, the location of the item, and present this information in a user friendly GUI that the everyman can use. First we will have to assemble a team that will consist of coders and a chemist to review existing literature to understand the gas sensing technology and how to transmit the data to the app. The next step is to purchase the components which consist of the C2Sense Gas Sensors or nanotube chemiresistive chips, smart fridge, and Smart Cameras.

We would then need to test the optimal placement for all the components in the fridge to maximize the accuracy of the sensors and the visibility of the cameras. Next we need to test the best way to transmit the data from the sensors to the app, whether wirelessly or wired. Afterwards create the Kitchen Aid app. Lastly test the system and continue improvements until we have a finalized product that can detect food spoilage, the location of the item, transmit this information to the app with an estimated expiration date, and allow the user to see the compartment at the location of the expiring item with the cameras to prevent food spoilage.

Preliminary Literature Review

Many gas sensing technologies have existed before, however recently a new method using chemiresistive nanotube chips has been developed. They chips can store and measure the quantity of gas in an area in a concentration of parts per millions. We chose to incorporate this technology due to its low cost compared to the older methods and its accuracy. To clarify the chips, will not be designed us but rather bought from C2Sense a leading company in nanotube gas sensing technology, which currently works with companies such as Agrofresh to sense gasses in fruit and poultry production.

The way these chips work is that they are programmed to identify and store particular gasses. The gases are released when bacteria break down food and release volatile Organic compounds (Ghasemi-Varnamkhasti et al., 2018). The nanotubes in the chip have a large surface-to-area that allows them to trap particular gas molecules. Also the nanotubes conduct electricity without releasing much heat. When the nanotubes are exposed to particular gases, their properties such as conductance changes allowing for gases to be identified by the sensor (Ghasemi-Varnamkhasti et al., 2018).

There are two options we will test for the gas sensor. The first will be RFID chemoreceptive chips. These chips use RFID (Radio-frequency identification) where encrypted data is transferred to a reader through radio waves which can be read by a cell phone or the smart Fridge monitor. Therefore the chip will collect the data and transfer the data to the app through radio waves (Occhiuzzi et al., 2011). Currently this technology is used to They are advantageous since they do not need a power supply, are low cost and can communicate to devices wirelessly. However they has the disadvantage of having a small range for transferring the radio waves to the reader (Occhiuzzi et. al., 2011).

The next option would be to use the gas sensors node device that C2Sense is currently using commercially. The gas sensor node has the advantage of already being developed and not needing to be close to the reader such as the RFID chip. We would just need to program the device to sense the gasses that produce releases as it begins to expire. We believe that the node might be pricier than the chip. Both of these options are viable since they both use nanotube chip technology for sensing the gas and collecting data allowing for a sensor with low cost and high accuracy.

These technologies exist in the market currently in the detection of food spoilage in food production and storage, but we intend to adapt this technology for residential homes. During the testing process we will test both methods to decide which option is more applicable for the smart Fridge setting.

Technical Description

The system once in place will have all the components in the smart refrigerator. Once the food begins to rot, the sensors will detect the gases, the quantity and the location of the item. The sensor will then transmit the data to our Kitchen Aid app. If we decide to use the RFID chip, then the information will be sent through radio waves. If we decide to use the node sensor, most likely we will transmit the data through wires or possibly bluetooth. The data will be interpreted by the app. The app will send a notification to the smart fridge and your cell phone (if you have the app downloaded on your phone). The app will display the location of the item in you fridge with an estimated time frame for consumption using colors. Red color highlight says that the food in that specific compartment has gone bad and yellow color shows that it will go bad soon but we we can still consume it. Lastly, you are given the option to see the inside of the spoiled food compartment using the smart cameras installed in all the compartments. The process is shown below:

Fig. 6A – Sensor sensing rotten food.

Fig. 6B – Notification on a smartphone.

Fig. 6C – Kitchen Aid app on a smartphone.

Fig. 6D – App interface.

Fig. 6E – Camera view of rotten food when user checks red box.

Fig. 6F – Camera view of food when user checks yellow box,

Budget

Our budget will cover all members specified salary costs, the rental of the Willie Laboratory, and all materials necessary for creating our application. The Willie Laboratory is important because it specifically caters to the use of chemists working with identifying, manipulating, or otherwise experimenting with gas compounds (such as the popular ethylene gas that is released when fruits are rotting). It is also important to sustain all members their designated salary, including all benefits such as health care and social security.

This will also cover the necessary materials, including the personal computers, gas sensors, etc. Our budget is roughly estimated to cover extraneous copies of the processor to suffice for any misplaced, damaged, or otherwise non-working sensors. However, after the first two months of working with the processors, we will have a better say on whether more supply is necessary to allocate from our budget.

Personnel

| Item | Cost | Time | Total Price |

| Doctoral Researcher (Chemist) | $120,000 | Annual | $120,000 |

| Software Engineer | $80,000 (X4) | Annual | $320,000 |

Total : $440,000

Equipment

| Item | Cost | Time | Total Price |

| Smart Fridge Cam | $150 (X15) | One-Time | $2,250 |

| CNT-Based Gas Sensor | $40 (X40) | One-Time | $1,600 |

| Samsung ENERGY STAR® Smart Wi-Fi Refrigerator with Family Hub™() | $3,995 (X2) | One-Time | $7,990 |

Total : $11,840

Lab Space

| Item | Cost | Time | Total Price |

| Willie Laboratory | $3,150 | Annual | $2,950/year |

Total : $2,950

Total Fixed Costs: $454,790

Appendix A – Task Schedule

References

Ghasemi-Varnamkhasti, M., Apetrei, C., Lozano, J., & Anyogu, A. (2018). Potential use of

electronic noses, electronic tongues and biosensors as multisensor systems for spoilage examination in foods. Trends in Food Science & Technology, 80, 71-92. doi:10.1016/j.tifs.2018.07.018)

Key facts on food loss and waste you should know! (n.d.). Retrieved from http://www.fao.org/save-food/resources/keyfindings/en/

Kumar, D., Kumar, I., Chaturvedi, P., Chouksey, A., Tandon, R., & Chaudhury, P. (2016). Study

of simultaneous reversible and irreversible adsorption on single-walled carbon nanotube gas sensor. Materials Chemistry and Physics,177, 276-282. p.1/ Retrieved 2018

Nguyen, H. Q., Ta, B. Q., Hoivik, N., Halvorsen, E., & Aasmundtveit, K. E. (2013). Carbon

nanotube based gas sensor for expiration detection of perishable food. 2013 13th IEEE International Conference on Nanotechnology (IEEE-NANO 2013). p.675/ Retrieved 2018

Occhiuzzi, C., Rida, A., Marrocco, G., & Tentzeris, M. (2011). RFID Passive Gas Sensor

Integrating Carbon Nanotubes. IEEE Transactions on Microwave Theory and Techniques,59(10), 2674-2684. doi:10.1109/tmtt.2011.2163416

Quested, T. E., Parry, A. D., Easteal, S., & Swannell, R. (2011). Food and drink waste from

households in the UK. Nutrition Bulletin,36(4), 460-467. doi:10.1111/j.1467-3010.2011.01924.x

Smarter FridgeCam. (n.d.). Retrieved from https://store.smarter.am/products/fridgecam

SCC. (2017, November 20). Phoebe Kwan VP BD, C2Sense at SCCPulse2017. Retrieved from

https://www.slideshare.net/Bristlecone_SCM/phoebe-kwan-vp-bd-at-c2-sense-at-sccpulse2017

What is RFID? (n.d.). Retrieved from https://www.epc-rfid.info/rfid

ZONE, C. (2017, December 19). Rotten Fruit In Fridge – Free Stock Footage. Retrieved from